Water Bottle Production Process And Method

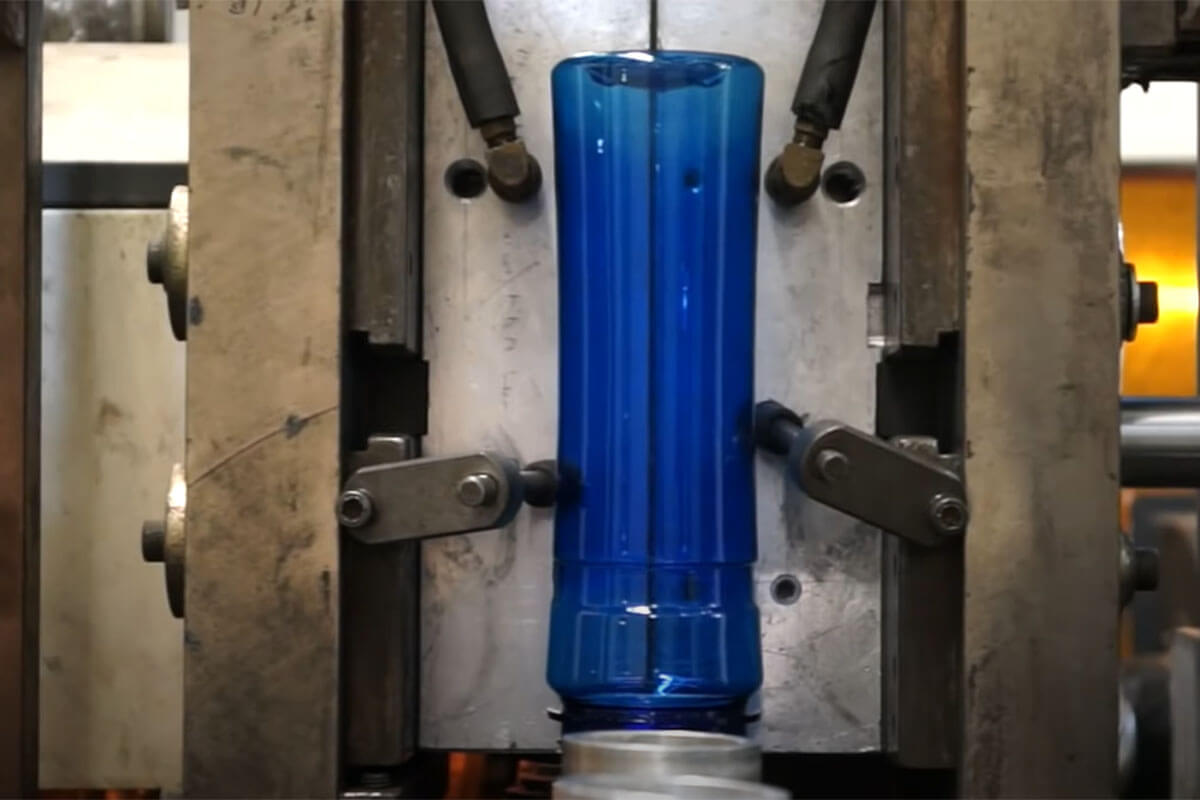

PP plastic water bottle stretch blow molding has two kinds: extrusion stretch blow molding and injection stretch blow molding. They use extrusion and injection methods to form parisons respectively. After the parison is formed, it is cooled to high elastic state or cooled to room temperature, reheated to high elastic state, and the temperature is adjusted to obtain the best orientation temperature; Then, the plastic reusable water bottle uses a stretching rod to stretch the parison axially, and then inflates it radially with compressed air later or at the same time; Finally, cool the bottle quickly.

PP plastic water bottle extrusion stretch blow molding

PP plastic water bottles can be molded by two-step extrusion stretch blow molding, one-step injection stretch blow molding and two-step injection stretch blow molding. Two step extrusion stretch blow molding uses the extruded pipe as the parison, so it is also called cold pipe stretch blow molding. After cooling, the extruded pipe is cut into predetermined lengths and stored. During stretch blow molding, the tube blank is clamped and heated in the oven; Then the neck thread is formed, and the end of the closed tube blank is formed as the bottom; After that, the tube blank and the core rod are transferred to the stretching and blow molding mold. At this time, the core rod acts as a stretching rod, and compressed air is injected to expand the tube blank radially, and finally cooled and shaped into a bottle.

PP plastic water bottle injection stretch blow molding

Axial oriented PP plastic water bottles are mostly formed by injection, stretching and blow molding. In the injection station, the injection machine equipped with typical PP screw is used to melt and homogenize PP. Through the balanced hot runner system, it is injected into the parison mold, formed into a bottomed tubular parison and cooled. After that, the parison rotates 90 ° with the turntable to the temperature regulating station to adjust the temperature distribution of the parison. After that, the parison is turned to 90 ° to the stretching / blow molding station, stretched, blown into bottles and cooled. The bottle is rotated 90 ° to the take out station.

Cncrown’s portable water bottle is made of food contact grade materials. It is firm, tough, durable, good sealing performance, and has exquisite and compact appearance, light weight, is easy to carry, and multi-purpose, can hold both liquid and dry goods. As a professional manufacturer of water bottles and lunch boxes, cncrown can produce plastic reusable water bottles for mass sale. The price is very competitive. Please contact us immediately!

Related Posts

How To Pack Lunch For Work? 12 Tips for Packing Food with Ease

Busting your food budget? Want to bring lunch to work? Here are some of the most effective tips to help you figure out how to pack lunch for work. Do you know the secret to living a long and healthy life? It’s eating home-cooked meals! It's not only the key to a...

What Is UV Printing ? Know Its Process and Advantages

Thinking of using UV printing? Read on to learn about its working process, benefits, drawbacks, and more to determine whether it is the right one for you.UV printing is a revolutionary printing technology that has made commercial printing easy and faster. The durable,...

How To Successfully Develop and Produce Bento Boxes: From Idea To Market

Introduction Everyone around us is surrounded by carefully designed objects every day, including the bento boxes, lunch bags, cutlery, etc. that we use every day, all carefully designed by a person or team. From a creative idea to a commercial launch, this is what...

0 Comments